Ronas Machine Capabilities

A list of the late model equipment we have in service.

UMC 500-SS - 24" x 16" x 16"

5-axis machining is an effective means to reduce setups and increase accuracy for multi-sided and complex parts. The shorter travels and compact footprints of the Haas UMC-500 Series Universal Machining Centers make them perfect solutions for 3+2 machining and simultaneous 5-axis machining of smaller parts. The UMC-500SS is equipped with a faster spindle, high-speed tool changer, and high-speed trunnion table to reduce cycle times and boost productivity.

ST-28Y - 9.4" x +/-2" x 22.4" - 4" Bore

Our ST-28Y turning center combines the heavy-duty A2-8 spindle head of our mid-size ST-35Y big-bore lathe with the compact footprint of our smaller ST-25Y to create a powerful turning center that provides heavy-duty cutting capability, without taking up a lot of valuable shop floorspace. The addition of Y-axis, C-axis, and live tooling allows milling, drilling, and tapping on the face of the part and around the circumference, for increased machine capabilities.

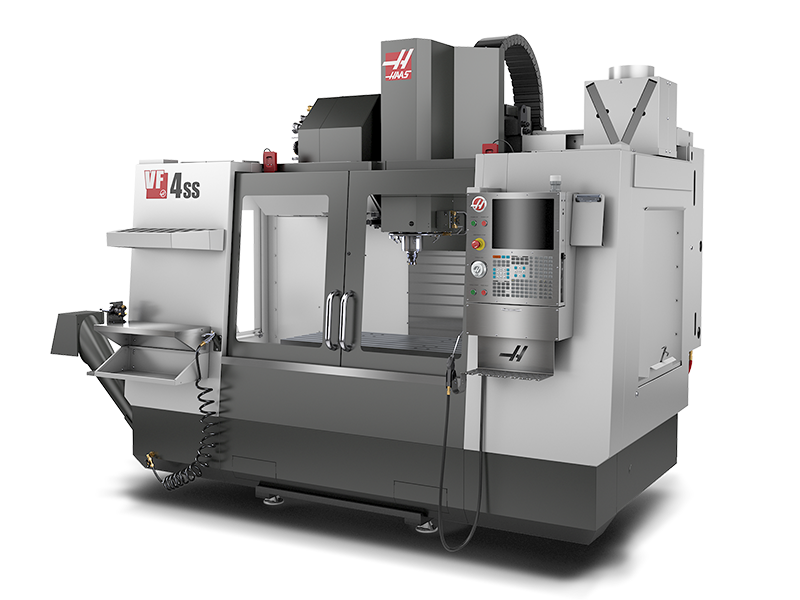

VF4-SS - 50" x 20" x 25"

The Haas high-performance Super-Speed vertical machining centers provide the high spindle speeds, fast rapids, and quick tool changes necessary for high-volume production and reduced cycle times. Each SS machine features a 12,000-rpm, inline direct-drive spindle, an ultra-fast side-mount tool changer, and high-speed rapids on all axes.

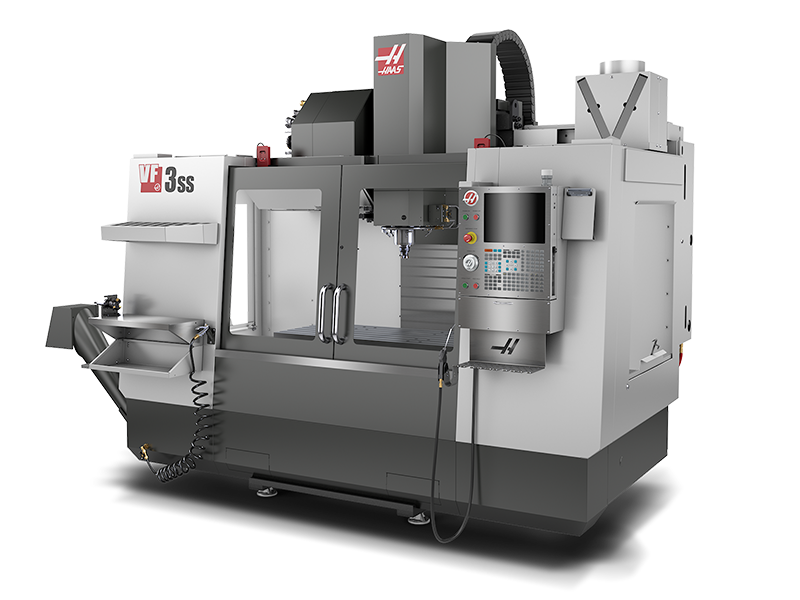

VF3-SS - 40" x 16" x 25"

The Haas high-performance Super-Speed vertical machining centers provide the high spindle speeds, fast rapids, and quick tool changes necessary for high-volume production and reduced cycle times. Each SS machine features a 12,000-rpm, inline direct-drive spindle, an ultra-fast side-mount tool changer, and high-speed rapids on all axes.

Two VF2-SS - 30" x 16" x 20"

The Haas high-performance Super-Speed vertical machining centers provide the high spindle speeds, fast rapids, and quick tool changes necessary for high-volume production and reduced cycle times. Each SS machine features a 12,000-rpm, inline direct-drive spindle, an ultra-fast side-mount tool changer, and high-speed rapids on all axes.

Two DC-1 - 23.6" x 17.7" x 13"

The DC-1 is a traditional-style drill/tap machine with a 10,000-rpm BT30 spindle and high-speed turret-style tool changer to minimize cut-to-cut times and shorten cycle times.

Two HRT210HT 4th Axis Rotaries

The Haas HRT210HT rotary table uses a high-torque servomotor to provide 385 ft-lb (522 Nm) of spindle torque for heavy cutting – that’s 83% more torque than our standard HRT210. This rugged, heavy-duty table can be mounted vertically or horizontally, and chucks and fixtures can easily be bolted to the table using the six precision T-slots and center through-bore.

Automatic Bandsaw - 12" Diameter

Our in-house automatic bandsaw is a prime example, allowing us to run high-volume cutting for production orders around the clock. Because the saw operates unattended, we drastically cut down on labor and operational hours. This “lights-out” capability means we get the most out of every raw material bar, reducing waste and keeping your material costs as low as possible.